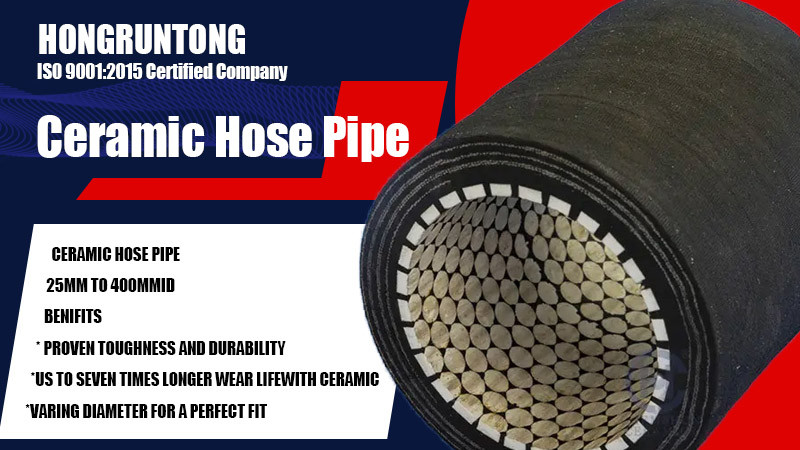

ATEX Certified Explosion Proof Ceramic Hose Lightweight Flexible

Acid Resistant

Brief Introduction

Designed for extreme heat environments, this hose features a 99.5%

alumina ceramic liner with a 316L stainless steel braid

reinforcement, capable of continuous operation at 800°C (peak

1200°C). The low-thermal-conductivity ceramic layer minimizes heat

transfer to external components, while the flexible metal sheath

accommodates thermal expansion. Ideal for foundry slag handling,

exhaust systems, and boiler feed applications. Compatible with

molten salts, hot gases, and abrasive particulates. Standard sizes:

DN25-DN400, with flanged or quick-connect fittings.

Specifications

| Item | Ceramic Rubber Hose |

| Model | HMCHP |

| Construction Features | Ceramics are inlaid into rubber pipes by vulcanizing process |

| Characteristic | Good flexibility and wear resistance |

| Applicable Medium | Powder/Paste |

| Outside Tube Material | Rubber |

| Inner Tube Material | SHC/SHN/SHA |

| Max Diameter | 300mm |

| Weight | Super light |

| Wear Resistance (compared with steel tube) | 15 times |

| Corrosion Resistance | Good |

| Heat Resistance | 100°C |

| Pressure Resistance | 2.5MPa |

Inner Diameter | Working Pressure | Burst Pressure | Length | Wall Thickness |

mm | (Mpa) | (Mpa) | (m) | (mm) |

300 | 0.4-1.2 | 3.6 | 1-3 | 34-37 |

414 | 0.4-1.2 | 3.6 | 1-3 | 35-37 |

560 | 0.4-1.2 | 3.6 | 2-3 | 40-45 |

600 | 0.4-1.2 | 3.6 | 2-3 | 40-45 |

700 | 0.8-1.5 | 4.5 | 2-3 | 40-45 |

800 | 1.2-2.5 | 5.5 | 2-3 | 50-52 |

900 | 1.5-2.5 | 7.5 | 2-3 | 55-58 |

1000 | 2.0-2.5 | 7.5 | 3-5 | 75-78 |

Why Hongruntong Ceramic Hose Pipes?

► UV Resistant Exterior

Special polymer jacket maintains integrity in outdoor

installations.

► Energy Efficient

Low thermal conductivity reduces heat loss in process applications.

► Vibration Dampening

Reduces noise and pipe fatigue in high-flow systems.

► Sustainable Solution

100% recyclable materials with 5-7 year service life reduces waste.

Key Features

► Slurry Transport – Handles abrasive ores (iron, copper) with

60-80% solids content

► Tailings Disposal – Resists corrosion from acidic/alkaline mine

wastewater (pH 1-14)

► Hydraulic Mining – Withstands 15MPa pressure for high-velocity

water-sand mixtures

Why Choose Hongruntong Marine?

► Three Decades of Specialization - Exclusive focus on ceramic hose

pipe R&D and manufacturing since 1993

► Proprietary Ceramic Formulation - Patented Al₂O₃/ZrO₂ composite

ceramic with 99.8% purity for maximum wear resistance

► Military Grade Quality Control - Implement ISO 9001:2015 with

MIL-STD-1916 sampling standards

► End to End Vertical Integration - From ceramic powder processing to

final assembly under one roof

FAQ

1. What makes ceramic hose pipes superior to traditional

rubber/steel hoses?

Our ceramic-lined hoses offer:

10-15x longer lifespan in abrasive applications (ASTM G65 verified)

Zero corrosion even with 98% acids or 50% alkalis

Weight savings up to 40% vs. steel pipes with equal pressure rating

2. What temperature/pressure limits do your hoses handle?

Standard range: -60°C to 800°C (peaks to 1200°C with special

grades)

Pressure ratings: Up to 25MPa static, 15MPa dynamic (higher on

request)

3. Are these hoses suitable for explosive environments?

Yes. We offer ATEX/IECEx-certified models with:

Conductive ceramic lining (<10⁶ Ω surface resistivity)

Anti-static outer layers (for Zone 1/21 hazardous areas)

4. What industries commonly use ceramic hose pipes?

Key applications include:

Mining: Slurry transport (80% solids)

Chemical: HF acid transfer (special ZrO₂ lining)

Steel: Molten slag handling (1300°C rated)

Food: CIP/SIP-compatible sanitary lines

5. How is the ceramic lining secured against detachment?

Our proprietary interlock system:

Mechanically bonds ceramic tiles to substrate

Withstands 5x standard bend radius without cracking

Passes 50,000+ flex cycles in validation tests